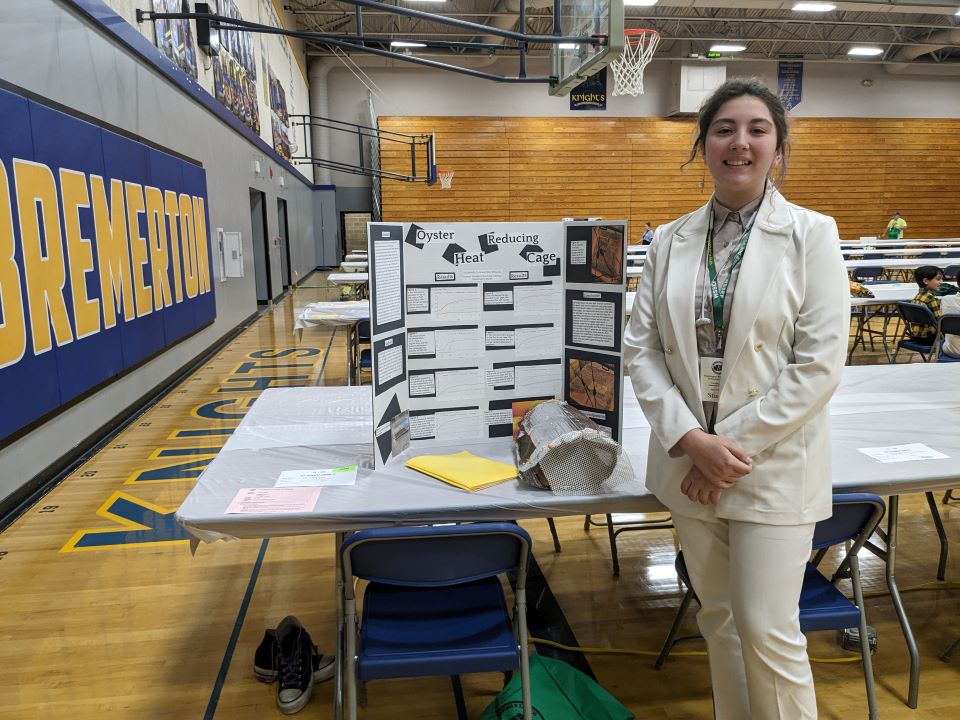

Middle Schooler gets to the pointe with her ballet-inspired research

Through the Society for Science, The Lemelson Foundation gives $100 awards to outstanding young inventors in Society Affiliate Fairs around the country. This prize was especially created to reward middle school inventors whose projects exemplify the ideals of inventive thinking by identifying challenges in their communities and creating solutions that will improve lives.

The New York City Ballet’s 95 dancers reportedly go through 8,500 pointe shoes, special shoes worn by ballerinas to allow them to dance on the tips of their toes, in one season. Middle schooler Austin Henderson from Gardendale, Alabama has been ballet dancing for nine years and began to wonder why ballet shoes are covered in satin, which is such delicate material.

“Over time, the fabric wears away as the shoe breaks down,” Austin explained.

This is Austin’s fourth year “on pointe” and her shoes only last about nine months. For a professional dancer, like the dancers at the New York City Ballet, a pair might only last for two days to a week. The Pittsburgh Ballet Theatre says they spend about $100,000 a year on pointe shoes for their ballerinas.

Austin’s project, “Get to the Pointe!,” which earned her the Lemelson Early Inventor Award from the Alabama Science and Engineering Fair, examined what would happen if different fabrics were used. “By constructing an artificial leg, I conducted an experiment to test the durability of four different fabric materials during simulated dance turn rotations at the tip of a pointe shoe,” Austin explained.

“The materials varied in weight (or thickness) and natural composition of the fibers. My hypothesis was that a similar synthetic fabric would be able to last longer under friction and pressure than the naturally delicate satin material. Through three trials, I was able to prove my hypothesis that Lycra could outlast satin, cotton and denim,” she said. Austin shared that she chose her fabrics because she wanted them to have comparable qualities. “Cotton has a similar weight and fiber thickness as satin,” she noted. “Lycra has a similar sheen and stretch. Denim was included out of sheer curiosity in durability due to its thickness; it has a reputation for being a durable material for work apparel.”

There are three key areas of pointe shoes that can factor into the deterioration of the shoe: the outer satin covering; the shank, which supports the arch of the foot and the toe block, which supports the weight of the dancer. The fabric, which Austin chose to focus on, was the quickest to break down.

“First I created an artificial foot and leg and threaded them through a hole in a stand and attached a handle to the top of the leg,” Austin explained. She used a shoe shaper/stretcher because it is already designed to fit the shape of a shoe. Austin then turned the “leg” in an upright position to simulate a ballerina turning on pointe.

“Using a manufactured pointe shoe, I took a 10×20-inch piece of fabric, and beginning at the platform or toe of the shoe, I tightly pulled the fabric up the shoe and secured the excess fabric around the shank of the shoe with a rubber band. I then slipped the artificial foot and leg into the wrapped shoe,” Austin said. She turned the shoe approximately 100 rotations every 56-58 seconds. After 100 rotations, she checked the platform of the shoe to determine whether any holes had formed. “Once a breakdown had been detected, I recorded my data.”

Although Austin found that Lycra did last longer, she also found that the material required more force to maintain consistent rotation speed, which, for example, means that the dancer would need to exert more effort to spin.

Austin reported that the most difficult part of the invention process was researching the fabrics because most pointe shoe companies focus more on the shoe structure, rather than the fabric. Her favorite part was finding her results. She commented, “Receiving this prize, has given me encouragement and confidence to pursue other scientific opportunities.”