Aswath Rajesh

8th Grade, DeLaura Middle School

Satellite Beach, FL

Aswath improved his previously developed eco-friendly plastic alternative by adding chitosan, a substance that comes from crustacean shells.

Ecofriendly Polymeric Material: Paving the Way for Circular Bio-Economy

VIEW POSTERProject Background

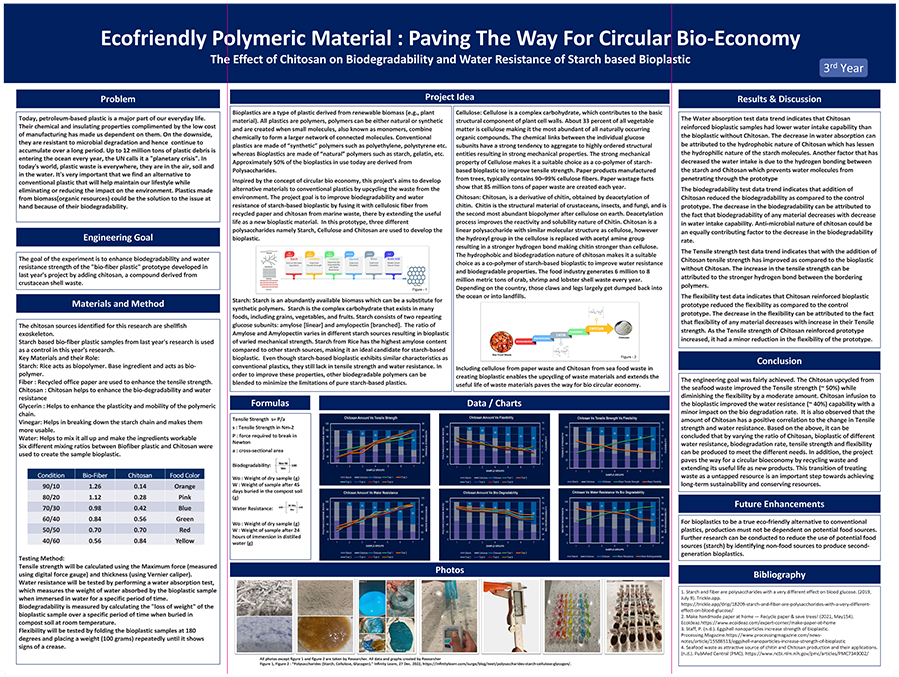

“Plastics take centuries to biodegrade, and they end up in oceans, rivers and landfills,” Aswath says. “After discovering the detrimental effects caused by plastics, I was motivated to find a solution for plastic pollution.” He searched for eco-friendly alternatives and discovered that plastics can be made of either human-made or naturally occurring polymers, chains of molecules. Natural polymers, like starch, break down more easily in the environment than synthetic ones. Many can also be found in products considered waste. So, Aswath decided to make a biodegradable plastic with chitosan, a substance that comes from the shells of crustaceans like crab, shrimp and lobster. Aswath worked on improving the water resistance of a plastic alternative he previously developed.

Tactics and Results

Aswath made several bioplastics that contained three natural polymers: starch from rice flour, cellulose from newspaper and chitosan from seafood waste. His bioplastics contained different amounts of chitosan, and a control that contained none. Once created, he tested the seven bioplastics’ properties. Aswath pulled on the bioplastics with a gauge to measure their tensile strength, submerged them in water for water resistance, folded them to test flexibility and put them in soil to see how quickly they biodegraded. The bioplastics with chitosan were less flexible and broke down more slowly than the control. But the bioplastic made of 60% chitosan, the highest amount, had 50% greater tensile strength and was 40% more water resistant compared to the bioplastic with no chitosan. The properties also change depending on how much chitosan is included. So, varying the amount can create bioplastics that meet different needs, Aswath says. He also notes that “by redirecting waste from landfills, it enables the utilization of valuable resources that would otherwise go to waste.”

Beyond the Project

Starch from rice flour was used as the base ingredient for these bioplastics, but it’s a food source, Aswath says. A different source of starch would make the products more sustainable. “If bioplastics can be produced using 100 percent waste materials, a true bio-circular economy can be achieved,” he says.

Other interests

Aswath enjoys piano, guitar, soccer, tennis and taekwondo but he especially loves playing chess. “The game’s strategic nature keeps me engaged and tests my thinking abilities,” he says. “I have to concentrate, think strategically and predict my opponent’s moves.” He would like to become an environmental engineer to help build a better future.