Akshadha Mehta

7th Grade, Dodgen Middle School

Marietta, GA

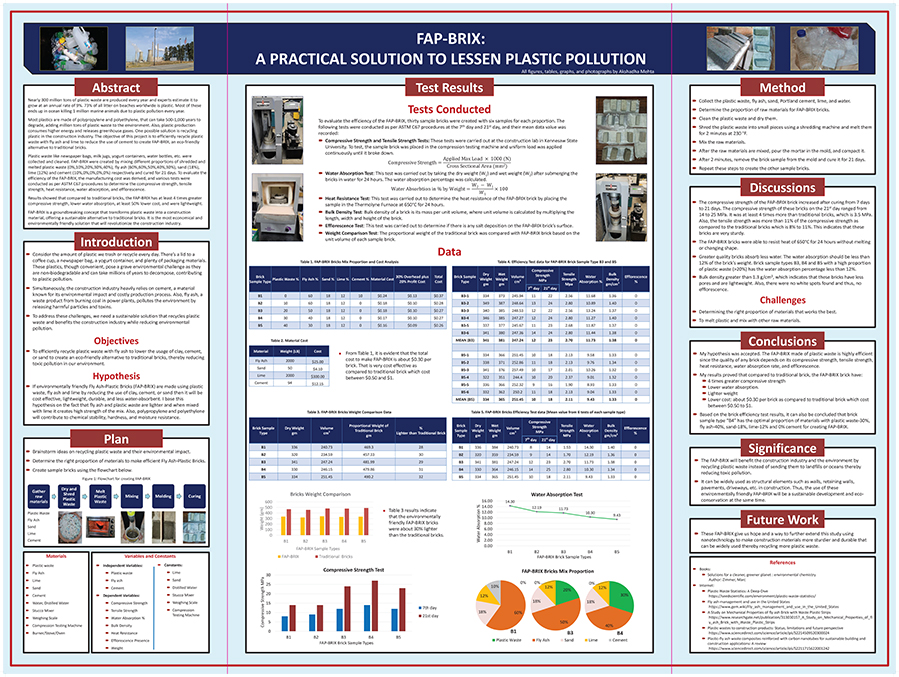

Akshadha turned plastic waste into bricks called FAP-BRIX, hoping to create a practical solution to lessen plastic pollution.

FAP-BRIX: A Practical Solution To Lessen Plastic Pollution

VIEW POSTERProject Background

“Every time I go to the beaches or trails, I notice that most of all litter would be plastic,” Akshadha says. Plastics are made of non-biodegradable materials and are used all the time. Akshadha read a recent study that estimated nearly 300 million tons of plastic waste are produced each year, and experts predict that number will continue to rise. She also learned that clay and concrete bricks are widely used in the construction industry, but their production is expensive and harmful to the environment. So, Akshadha wanted to solve both problems by turning plastic waste into an alternative type of brick.

Tactics and Results

Akshadha collected materials for her bricks, called fly ash-plastic bricks, or FAP-BRIX, that included fly ash, a byproduct of burning coal, as well as shredded plastic waste, sand, lime and water. She mixed together the materials to make four brick varieties with different proportions of plastic waste and fly ash. She also made bricks with cement instead of plastic waste as a control. Akshadha evaluated many of the bricks’ properties, including their strength, water absorption, heat resistance, weight and density. Bricks take a long time to dry so she tested them on day 7 and day 21. Using equipment at Kennesaw State University, Akshadha found that FAP-BRIX could hold more weight than traditional bricks. “This indicates these bricks are very sturdy,” she says. Her bricks were also about 30 percent lighter than traditional bricks. They did not melt when placed in a furnace that was hotter than 400 degrees Celsius, for 24 hours, and the bricks made of more than 20 percent plastic waste absorbed little water. The materials to produce FAP-BRIX were also less expensive than traditional bricks. Akshadha’s bricks cost $0.30 each, whereas a standard brick costs between $0.50 and $1 each. “FAP-BRIX is a practical solution to lessen plastic pollution,” Akshadha notes.

Beyond the Project

Nanotechnology could make the FAP-BRIX even sturdier and more durable, Akshadha says.

Other interests

Akshadha likes to dance and swim; she says swimming is “a peaceful form of exercise.” She hopes to become a medical doctor in the future because, “when patients become sick, their normal way of living is changed, but doctors can often bring their routine back,” Akshadha says.